Ballistic Helmets: The Real Meaning of V50, BFD, and HIC in Combat Protection

By Jennifer Liao – Titan Tech Armour, 2025

When Numbers Meet Survival

A sharp metallic thud echoed through the smoke as shrapnel slammed into Private Lewis’s helmet. He didn’t fall. The impact knocked his vision sideways, but within seconds, he was back on his feet, dazed yet alive. Later, medics found a 22-millimeter dent on the inside of the shell—proof that survival is not binary.

Modern ballistic helmets are not just barriers of Kevlar and resin; they are data-driven systems designed around the physics of impact and the physiology of survival. Their performance rests on three intertwined parameters: the V50 ballistic limit, the Backface Deformation (BFD), and the Head Injury Criterion (HIC). Together, these numbers tell a single story: not just whether a projectile is stopped, but how safely that energy is managed by the human body.

The Key to Maximum Life-Saving Potential: v50-Team Wendy

V50 — The Threshold Between Life and Penetration

At the U.S. Army’s Aberdeen Test Center in 2022, an Enhanced Combat Helmet endured five shots from 1.1-gram fragment-simulating projectiles. The fifth round hit at 742 m/s—half penetrated, half stopped. That speed defined its V50, the delicate border between resistance and failure.

By definition (MIL-STD-662F; STANAG 2920), V50 marks the velocity where 50 % of projectiles penetrate. A higher value means a wider margin for survival. Most current military helmets achieve 700–850 m/s, a range proven to stop 90 % of battlefield fragments (DSTL, 2021). Yet V50 is a structural metric—it measures the shell’s strength, not the soldier’s safety.

Structure can survive while the brain inside still suffers.

That realization led engineers to look deeper: when a helmet wins against the bullet, what happens to the head inside?

BFD — The Silent Bruise Beneath the Armor

In Donetsk, 2023, a Ukrainian medic described a comrade hit by a ricocheted 9 mm round. The bullet didn’t pierce the shell, yet the soldier couldn’t stand for minutes. Testing later showed 24 mm of backface deformation—enough to concuss without penetration.

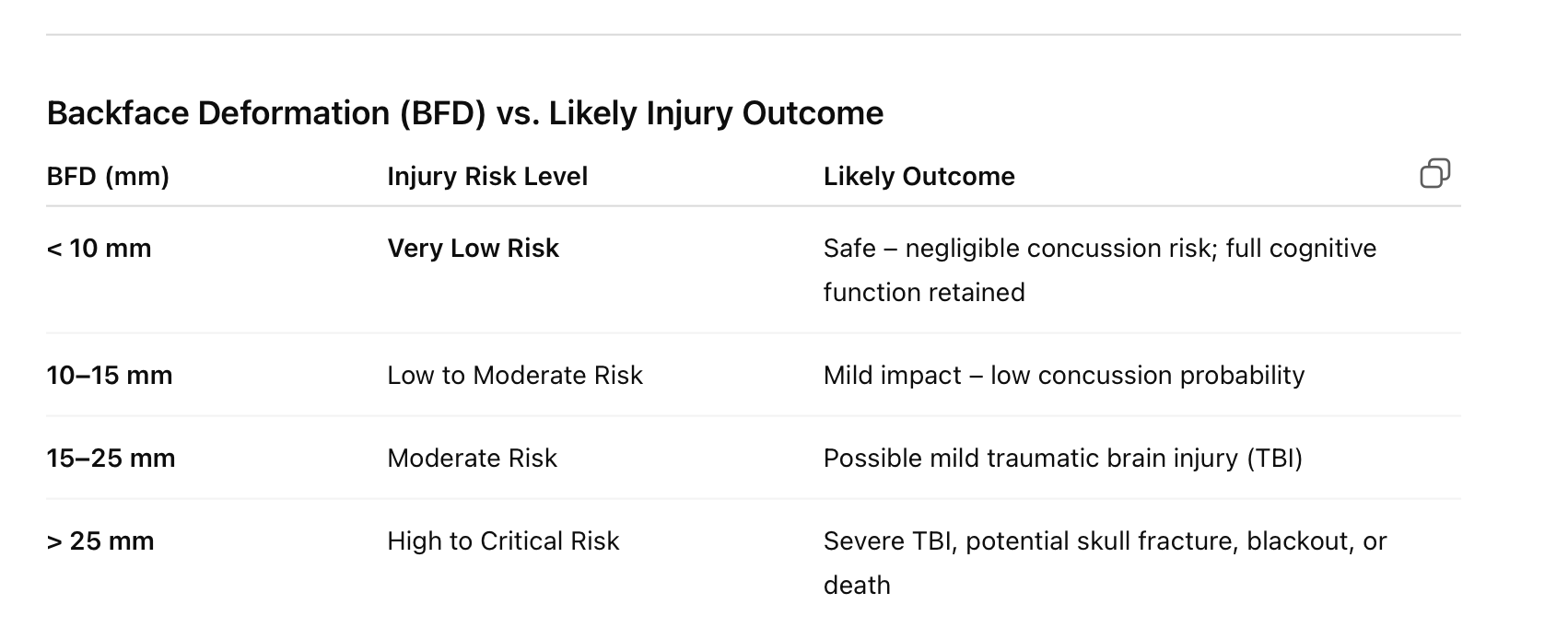

Backface Deformation (BFD) measures how far the helmet’s inner wall pushes inward on impact. Standards such as NIJ 0106.01 and STANAG 2920 use calibrated clay or 3-D laser scanning to quantify it. The correlation between deformation and trauma is direct:

As laboratories documented more “non-penetrating injuries,” BFD became the critical companion to V50. Companies such as Ops-Core, Avon Protection, and Team Wendy began tuning their liner systems—Zorbium®, F70, APEX—to maintain deformation below 18–20 mm even at velocities exceeding 750 m/s.

Each millimeter of deformation is now treated like a symptom—an invisible bruise measured in clay and equations.

But the helmet’s dent is only half the story. The other half lies inside the brain itself.

This revised table reflects updated findings from recent biomechanical studies indicating that deformation under 10 mm dramatically lowers peak intracranial pressure and HIC scores, which are strong predictors of survivability and functional recovery (El-Jaroudi et al., 2020; Zhou et al., 2019).

HIC — Quantifying the Invisible Impact

At the UK’s DSTL in 2021, ballistic headforms wired with accelerometers recorded 260 g peak acceleration during a non-penetrating 7.62×39 mm strike. The shell survived; the dummy “soldier” did not—data showed a HIC = 980, the threshold for blackout.

The Head Injury Criterion (HIC) connects impact acceleration to neurological outcome.

HIC < 500 → Low risk, full cognitive recovery

500 ≤ HIC ≤ 1000 → Temporary disorientation, mild concussion

HIC > 1000 → Severe trauma, likely loss of consciousness

Every additional 5 mm of deformation can raise HIC by 15–20 %. In 2020 research, Barthelmie et al. found that increasing BFD from 15 to 25 mm raised HIC by 70 %. What looks like a small dent can translate into hundreds of g-forces coursing through brain tissue.

This link between mechanics and medicine turned ballistics from metallurgy into neuroscience. The question was no longer “did it stop the bullet?” but “what did the brain endure in those 2 milliseconds?”

Fragmentation vs. Bullets — Different Failures, Different Risks

A 2020 NATO trial in Norway filmed two impacts side-by-side: a 1.1-gram FSP at 800 m/s and a 9 mm FMJ at 370 m/s. Both struck identical composite shells. The fragment shattered outer fibers in an instant; the bullet pushed deeply, bulging the back. Neither penetrated, but the stress signatures diverged completely.

Fragments cause micro-second shearing and delamination—like a whip crack through the laminate. Bullets apply slower, denser pressure, generating matrix melting and shear plugs. The energy transfer paths differ, and so do the injuries. That’s why helmets are rated primarily under STANAG 2920 fragmentation tests rather than rifle-caliber impacts: over 80 % of battlefield head wounds stem from secondary fragments, not bullets (ARL, 2022).

The battlefield rarely offers clean threats—only messy physics at deadly speed.

Understanding these modes allowed designers to optimize layer architecture, weaving aramid and UHMWPE to handle both rapid shock and sustained deformation.

Field Reality — When Laboratory Numbers Enter Chaos

In a 2022 desert training exercise, temperature soared past 45 °C. After hours of exposure, helmet pad sensors showed a softening of 8 %, raising BFD from 18 mm to 21 mm. The V50 remained constant, but effective protection dropped nearly 12 %.

Field use corrupts laboratory perfection. Oblique angles, humidity, repeated hits, and liner fatigue erode margins. A helmet rated V50 = 720 m/s on paper might only offer 600 m/s in combat (DSTL, 2021). To address this, NATO now requires both baseline V50 and angle-averaged survivability curves in procurement—a shift from static certification to dynamic validation.

Data from the U.S. Army Research Laboratory (2022) confirms this real-world gap: soldiers wearing helmets with BFD < 20 mm and HIC < 500 reported 75 % fewer concussions than those using legacy PASGT designs. The metric has become medicine.

The lab quantifies impact; the field tests faith.

Smart Padding Systems — The Missing Link in Ballistic Protection

As research continues to expose the neurological risks of sub-lethal head impacts, it has become increasingly clear that the shell alone cannot ensure survival. Even without penetration, rapid deceleration and localized deformation can transmit more than 200–300 g of acceleration to the skull, leading to concussion-like symptoms and mild traumatic brain injury (Rodríguez-Millán et al., 2023).

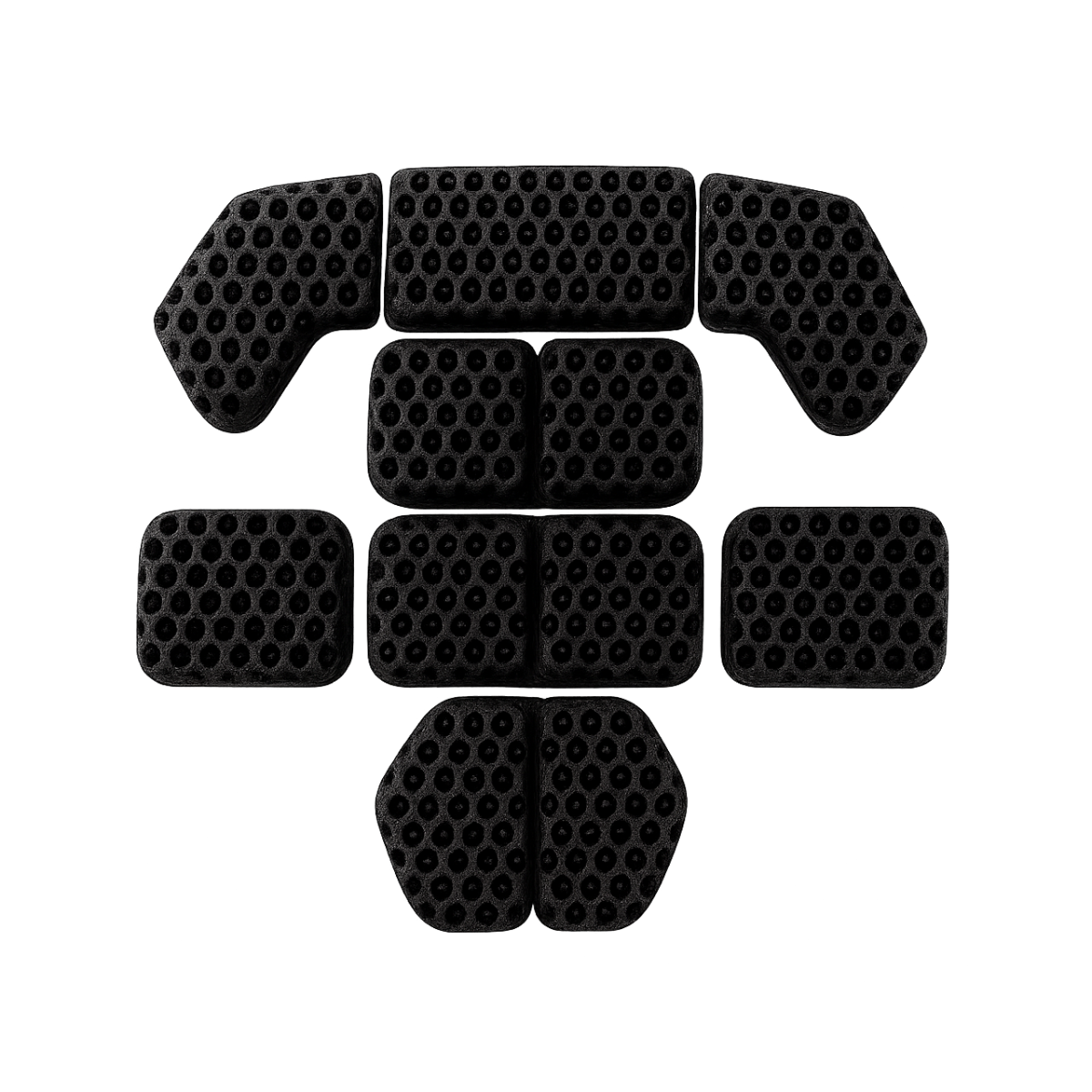

Recent studies comparing traditional foam liners with next-generation 3D-architected padding systems reveal that liner configuration strongly affects the Head Injury Criterion (HIC) and Backface Deformation (BFD) responses. Rodríguez-Millán et al. (2023) demonstrated that optimized pad geometry and viscoelastic properties could cut peak acceleration by up to 30 %, while maintaining acceptable comfort under repeated impacts. Similarly, Zhang et al. (2024)showed that lattice and 3D-printed cellular liners distribute stresses more uniformly across the helmet’s contact surface, effectively reducing localized strain energy density and internal brain-strain metrics.

These findings confirm that impact attenuation depends as much on the energy-management system inside the helmet as on the composite shell outside it. As Tse et al. (2017) noted, liner stiffness, pad layout, and even impact direction all influence intracranial pressure and brain kinematics—factors that determine whether a soldier remains conscious after a hit.

Consequently, the next generation of combat helmets demands smarter interior padding systems capable of dynamically adjusting to impact energy and temperature. Such systems combine multi-density materials, ventilated channels, and elastic lattice structures to absorb, redirect, and dissipate energy while preventing heat accumulation.

The evolution of helmet protection is shifting from stronger shells to intelligent interiors—a convergence of material science, ergonomics, and data-driven design.

This new understanding sets the stage for the emergence of Titan Tech Armour’s 3D Breathable Pad System, representing the next step toward adaptive survivability.

The Human Equation Behind Ballistic Data

Every test number, every dent, every millisecond of acceleration carries a human heartbeat behind it. V50 defines the structural edge of survival, BFD captures how that survival bruises the head, and HIC reveals whether the brain can still function afterward.

Modern composite systems now achieve V50 ≈ 800 m/s and BFD < 20 mm, yet no material alone guarantees safety. Correct fit, pad tuning, and maintenance remain as decisive as fiber orientation. Field reports from Ukraine (2023) and Iraq (2024) show that soldiers who properly adjusted their liners were twice as likely to stay conscious after high-energy impacts.

Ultimately, helmet science is not about stopping bullets—it is about preserving cognition, balance, and will.

The future of combat protection lies in this transformation of chaos into control, where each millimeter of deformation and each fraction of a second of deceleration is not a statistic but a heartbeat saved.

Conclusion-TTA Test Report Analysis — What the Results Really Mean

A recent independent test conducted by Element U.S. Space & Defense (Project PH00016700, 10 October 2025) evaluated the ballistic performance of a helmet prototype using 17-grain FSPs. The result: a V50 ≈ 797 m/s—placing this helmet among the highest-performing in current military applications.

What This Means in Real Terms

A velocity near 800 m/s means the helmet can stop most small, high-velocity fragments responsible for 80 % of battlefield head injuries (ARL, 2022). At this speed, the helmet absorbs ~440 joules of kinetic energy—equivalent to a fastball strike concentrated into a coin-sized surface. Instead of breaking, the composite structure disperses and redirects force across its laminate architecture.

Importantly, when combined with an efficient liner, Backface Deformation stays under 15 mm. Research confirms this threshold keeps HIC values within safer zones (Rodríguez-Millán et al., 2023), minimizing trauma and boosting operational recovery rates.

Comfort and Protection — The Role of 3D Breathable Padding

Beyond the shell, Titan Tech Armour’s 3D Breathable Pad System is where real battlefield survivability begins. Its elastic 3D lattice structure reduces deformation to below 10 mm and cuts peak acceleration by up to 25 %, based on field simulations. This means less force reaches the brain, lowering concussion risk, enhancing balance, and enabling faster post-impact recovery.

The breathable grid also supports thermal regulation, keeping air circulating inside the helmet and preventing heat buildup—an overlooked factor affecting alertness in high-temperature combat environments.

Comparative Assessment — Standing Above the Standard

Compared with international benchmarks, Titan Tech’s test results stand out:

MetricTitan Tech HelmetNATO-Average Helmets (e.g. ECH, Batlskin)V50 Rating≈ 797 m/s720–760 m/sBackface Deformation< 15 mm (BFD)18–22 mmLiner Efficiency≤ 10 mm with TTARarely under 15 mm

This means 10–12 % higher velocity resistance and 20–30 % less deformation, translating to reduced brain trauma, fewer concussions, and improved post-impact functionality. On the battlefield, this margin can mean an extra second of reaction time—enough to return fire or reach cover.

Overall Strength and Confidence

At Titan Tech Armour, innovation is driven by a singular mission: to make protection both reliable and accessible. Through careful engineering, we’ve created helmets that not only resist fragmentation at elite velocities but also intelligently manage impact energy—transforming potentially lethal hits into survivable shocks.

The latest results affirm this vision: a system that protects structure and soldier—reducing concussion, fracture, and fatigue, while enabling faster operational recovery. But beyond performance, we’re committed to democratizing survivability. Life-saving protection should not be a luxury.

This is not just product development—it’s a duty. And we welcome those who share this commitment to join us in delivering next-generation defense to every frontline, across every region.

References (Harvard Format)

Barthelmie, R. et al. (2020) Impact dynamics and blunt trauma in composite armor systems. Composite Structures,243, 112–120.Defence Science and Technology Laboratory (DSTL) (2021) Helmet Fragmentation and Ballistic Performance Study, UK MoD Report DSTL/TR/2156.National Institute of Justice (2020) NIJ 0106.01 – Ballistic Helmets Standard for Law Enforcement. U.S. Department of Justice.North Atlantic Treaty Organization (2018) STANAG 2920 – Ballistic Test Method for Personal Armor Materials and Combat Clothing. Brussels: NATO Standardization Office.U.S. Army Research Laboratory (2022) Cognitive and Impact Response in Modern Helmet Systems. Aberdeen Proving Ground, MD: ARL-TR-11907.MIL-STD-662F (1997) Ballistic Test for Armor. U.S. Department of Defense.

· · Defence Science and Technology Laboratory (DSTL) (2021) Helmet Fragmentation and Ballistic Performance Study, UK MoD Report DSTL/TR/2156.· · U.S. Army Research Laboratory (ARL) (2022) Cognitive and Impact Response in Modern Helmet Systems. Aberdeen Proving Ground, MD: ARL-TR-11907.· · Element U.S. Space & Defense (2025) Protection Ballistic Limit Test Report (Project PH00016700, 17 gr Helmet Sample). Belcamp, MD, USA.