Explosion proof

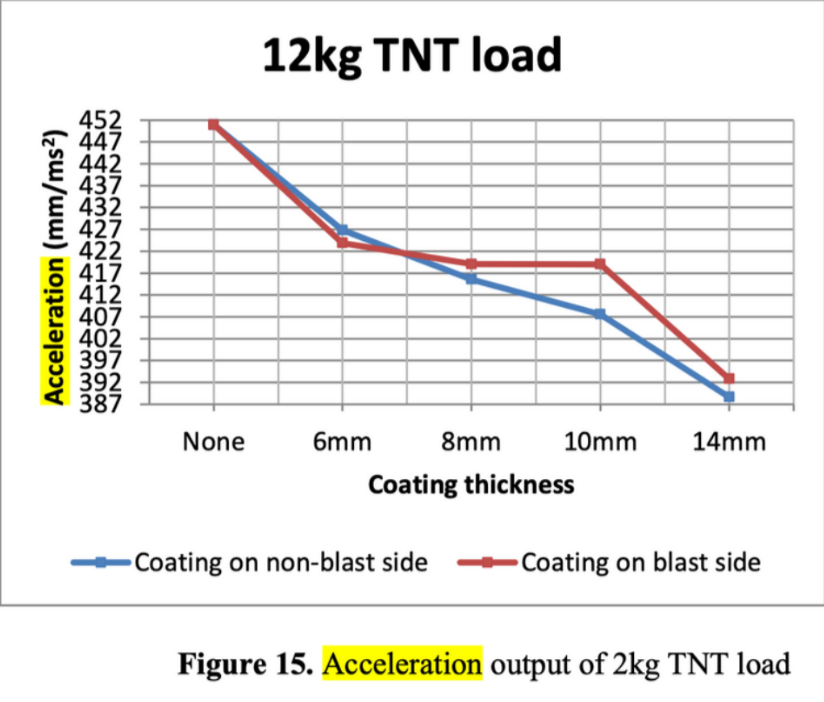

Acceleration output

Deformation output

external

Forticoat provides robust external protection for military vehicles by enhancing their resistance against shrapnel, blasts, and physical impacts when applied to surfaces such as tactical trucks, armored personnel carriers, and transport vehicles. In addition to impact protection, the coating safeguards vehicles from extreme environmental conditions, including high and low temperatures, moisture, and corrosive agents. When Forticoat is applied to localized areas such as the bottom steel plate of an armored fighting vehicle (AFV) hull, it significantly reduces the destructive impact of anti-tank explosions, thereby strengthening overall survivability and extending vehicle service life.

Internal

Forticoat provides comprehensive internal protection for military vehicles by reinforcing critical compartments and components. In the crew compartment, it shields walls and floors to absorb shock, enhancing occupant safety, while application on seat cushions—combined with our TTF (Non-Newton material shock absorption pad)—helps reduce spin-related injuries from explosions. In the engine compartment, Forticoat guards against heat, oil, and spills, while also reducing vibrations and noise. Applied to fuel tanks, it prevents leaks and corrosion, ensuring fuel system reliability. In ammunition storage areas, it delivers an additional layer of blast protection to minimize explosion risks. On interior panels and electronics, it defends against moisture, dust, and physical damage, preserving system integrity. Finally, when used on seats and restraints, Forticoat enhances comfort and durability while providing critical shock absorption to further improve crew safety.